Differences of DTF with DTG and White Toner

In the last news, we talked about 3 points of the DTF(Our DTF transfer film). Today, Hanrun will continue our topic. If you haven't read last news, please click here to read part 1.

1. Differences of DTF with DTG and White Toner

DTF is a mix between these two techniques and it will create some confusion when comparing, because they have certain similarities. We are going to do an analysis of their differences so that it is easier for you to identify which technique best suits your needs.

1.1 Differences between DTF and DTG

DTF and DTG (direct printing on textile) are very similar acronyms and both techniques are based on a jet printer equipped with white ink ... What are the differences between the two?

The initial investment: The DTF technique represents a very low investment compared to a DTG textile printer. Practically a DTF equipment costs a tenth of a DTG printer.

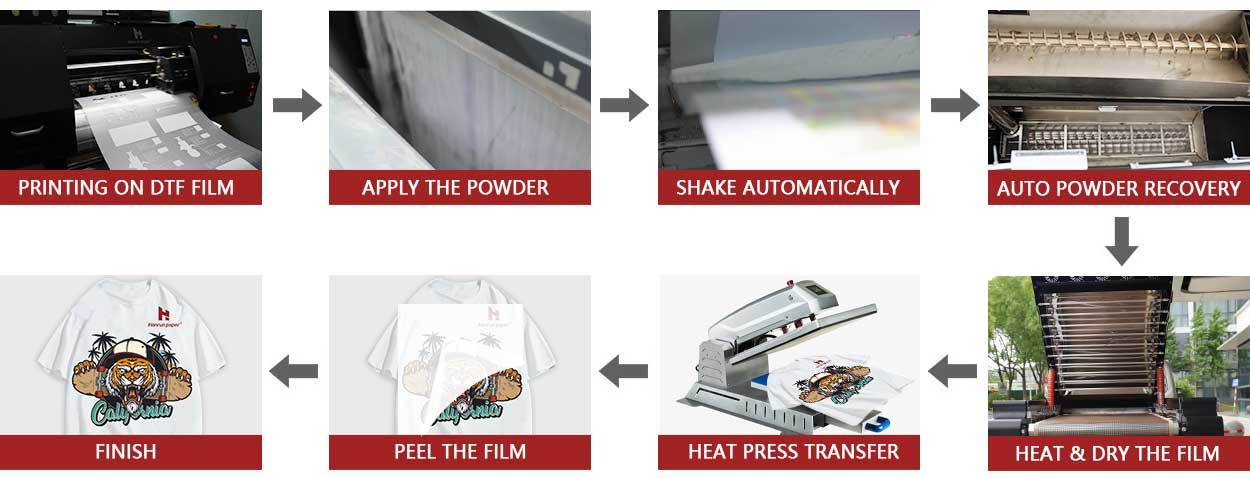

Production time: In DTF, the film is first printed on, to which the DTF powder must be added later, the printed film is cured and then the film design is transferred to the textile. While with the DTG technique the printer prints directly on the garment or fabric, which greatly shortens the production time compared to DTF.

Finish and feel of the print: The DTF has a somewhat "plasticized" finish very similar to the finish of a silk-screen transfer or cut textile vinyl, however, they are very elastic inks that prevent cracking of the print when stretching the garment. With the DTG technique, a much finer finish is achieved to the touch and integrated into the fabric, since the ink remains totally impregnated in the fabric.

Intensity and purity of the White color: In this case the DTG technique is the one that achieves a white of greater intensity and purity. In the DTF technique the white is not so pure and intense.

Cost of consumables: Both techniques have low production costs. A priori, it may seem that the DTF is going to become more expensive due to the need for more materials in the printing process, but the truth is that the final cost of the printed shirt is somewhat lower with DTF than with DTG.

1.2 Differences of DTF with White Toner

Here the similarity resides in the production process, since we must first print the transfer and then stamp the shirt with the printed transfer and the result is very similar to the touch as well. We are going to analyze the differences between DTF T-shirt personalization and low cost white toner.

Initial investment: In this case, a DTF equipment is also cheaper than a laser printer since the cost of a DTF equipment is half that of a laser printer such as Uninet or OKI.

Printing process: DTF is much simpler than white toner since it prints the white layer at the same time as the color layer (in the case of low-cost white toner machines).

Pelado transfer FOREVER NO CUT: With white toner you must iron the printed paper A to the paper B that incorporates the adhesive and then peel. This step is very delicate since if the peeling is not done correctly, the transfer will be damaged and it will cause you to lose production at no cost. With the DTF technique this step does not exist, which saves you time and money in possible waste.

Finish and feel of the print: The finish to the touch is practically the same with both techniques. The biggest difference is that DTF inks are textile and provide greater elasticity and resistance to cracking.

Intensity and purity of the color White: In this case, the white toner technique achieves a more intense white.

Consumables cost: White toner has much higher printing costs than DTF due to the toners and NO CUT transfer papers needed to perform the stamping. More or less, a DTF printed shirt has a production cost of 50% less than a White Toner printed shirt.

Variety of possible projects: DTF is a technique in which you can mainly work with textiles, while the laser technique with white toner opens up a wide range of projects, since in addition to textiles you can customize full color rigid.

2. For whom is the DTF technique suitable?

It is a perfect technique for all those who are interested in introducing the customization of T-shirts and any other textile (cushions, masks, bags, sweatshirts ...) in their cotton , polyester or any color mix business with a very low investment .

If you already practice sublimation of articles, the DTF is a perfect complementary technique to get more economic performance from your business.

If you have any questions or concerns about DTF technology and customizing t-shirts, do not hesitate to contact us. Hanrun is a professionable factory in heat transfer industry, we can provide you with the whole solution.

Contact Us

Global sales e-mail: info@hanrunpaper.com

Global sales WhatsApp: 86 189 3686 5061

Address: No.10 building, Baijiahui Innovation Community, 699-18 Xuanwu Avenue, Nanjing, China

Transfer To Digital, Transfer To Future

Contact us

Address:No.10 building, Baijiahui Innovation Community, 699-18 Xuanwu Avenue, Nanjing, China