Why Choose Hanrun Paper DTF Film?

In the fast-evolving world of digital textile printing, the quality of DTF (Direct-to-Film) transfer film is paramount to achieving vibrant, durable, and precise prints. Hanrun Paper Co., Ltd., a leading innovator in the digital printing industry, has developed a cutting-edge DTF PET transfer film that sets new standards for performance, reliability, and versatility. Engineered to seamlessly integrate with EPSON, Roland, and Mimaki DTF printers, our film ensures smooth operation, exceptional print results, and consistent performance across various fabrics, from cotton to synthetic blends.

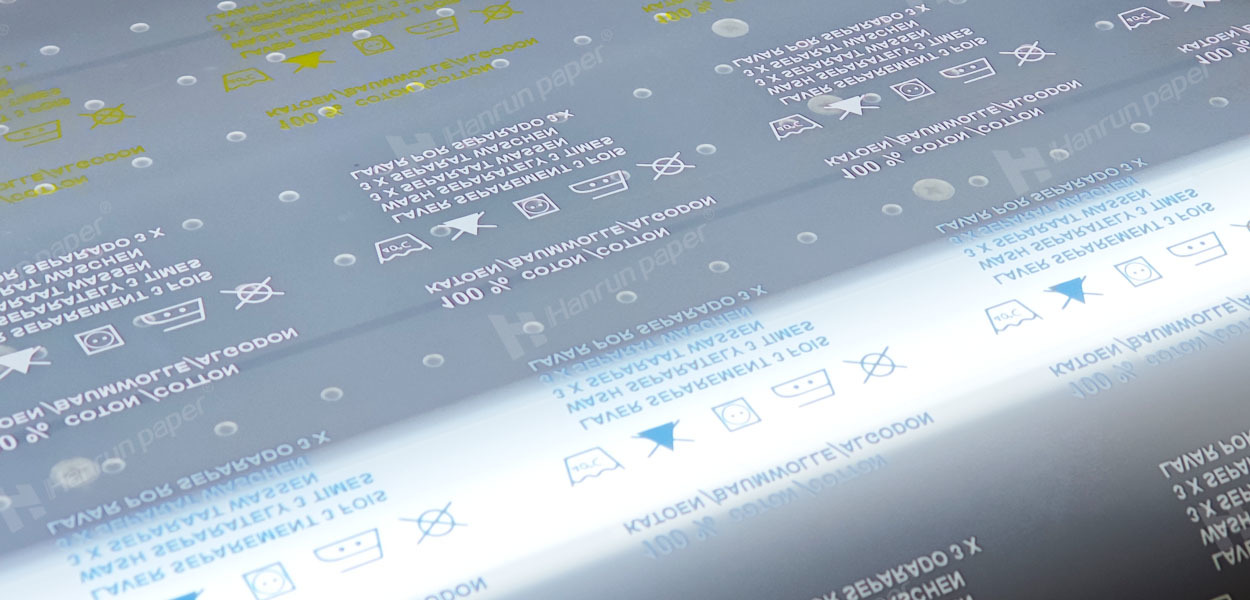

Advanced Coating Technology for Superior Print Quality

Hanrun paper DTF film features a multi-coating design – an organic silicon protective coating, a thermal release coating, and a water-based ink-absorbing medium coating – working in tandem to deliver unmatched printing performance:

High Ink Absorption: The water-based ink-absorbing layer efficiently captures and locks in ink, preventing bleeding and ensuring vivid, true-to-color prints even with high-ink-volume applications.

Enhanced Wash Resistance: The multi-layer structure significantly reduces color fading after repeated washing, making it ideal for garments that require long-lasting durability.

Smooth Surface & Uniform Coating: The organic silicon protective layer ensures a smooth, scratch-resistant surface, while the thermal release coating enables easy peeling after heat pressing, leaving no residue on the fabric.

These features make our film perfect for detailed designs, fine text, and complex gradients, ensuring every print is sharp, vibrant, and professional.

Engineered for Compatibility and Efficiency

Understanding the importance of seamless integration with DTF printing equipment, Hanrun paper DTF film is rigorously tested to work flawlessly with EPSON, Roland, and Mimaki DTF printers. Whether you’re using desktop models for small batches or industrial-grade machines for large-scale production, our film guarantees:

Consistent Performance: Uniform ink absorption and smooth feeding prevent printer jams and ensure stable, high-speed printing.

Versatile Applications: It is suitable for a wide range of fabrics, including cotton, linen, polyester, and blended materials, making it a one-stop solution for diverse printing needs.

Time and Cost Savings: The easy-to-use design minimizes waste, while the fast-drying and quick-peeling properties streamline the production process, boosting overall efficiency.

Uncompromising Quality Control for Reliable Results

At Hanrun paper, quality is not just a promise – it’s a process. Our DTF film undergoes a rigorous 8-step testing protocol to eliminate defects and ensure every roll meets our high standards:

Multiple Internal Coatings: Ensures uniform layer thickness and adhesion.

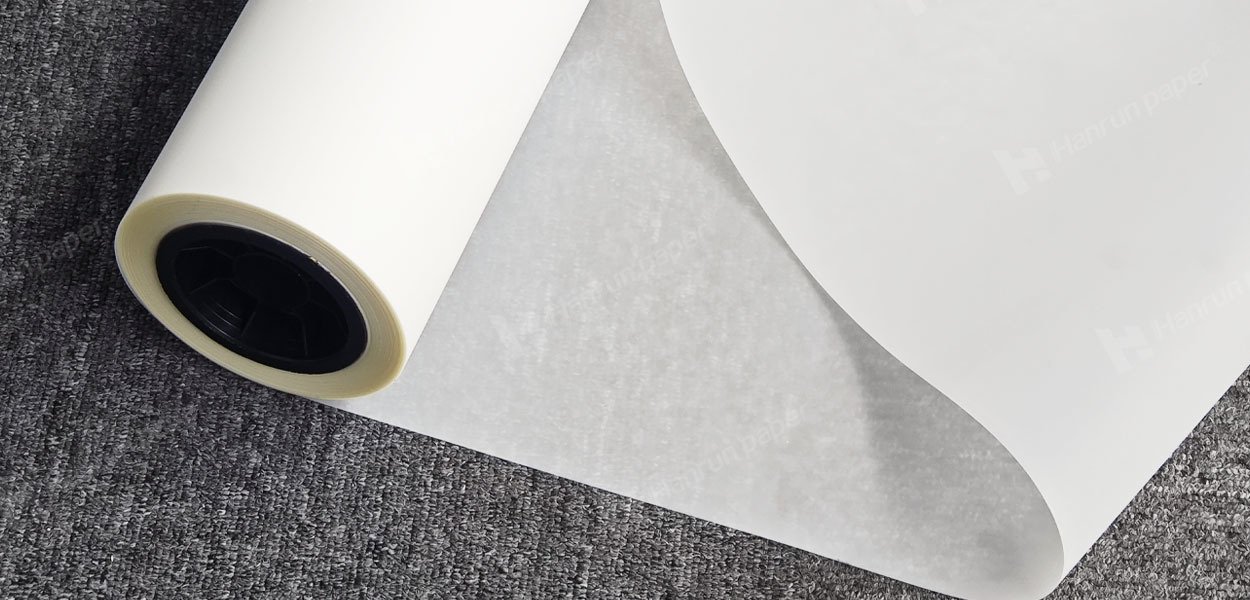

Film Thickness Testing: Maintains a precise thickness of 100μm with a tolerance of ±2μm for consistent performance.

Core Thickness Inspection: Prevents misalignment during printing.

On-Machine Testing: Samples are tested for print clarity, ink absorption, color vibrancy, powder shaking efficiency, and high-temperature resistance.

Peel Test: Checks for clean, residue-free peeling after heat pressing.

Wash Resistance Test: Samples are washed 50 times at 60°C to ensure no color fading or pattern loss.

Quantity and Packaging Check: Ensures accurate counts and secure packaging for safe delivery.

Final Shipment Inspection: Double-checks all quality parameters before dispatch.

With our patented technology (Patent No.: 202110519575.4) and OEKO certification, you can trust that our film is safe, reliable, and free from hazardous substances.

Solving Common DTF Printing Challenges

The market is flooded with low-quality DTF films that cause poor ink absorption, uneven color, and residual powder. Hanrun paper film addresses these problems head-on:

Ink Bleeding and Smudging: Our advanced coating technology ensures controlled ink diffusion, keeping text and edges sharp even for intricate designs.

Powder Residue: The smooth thermal release layer allows for clean powder shaking, leaving no excess powder on non-printed areas.

Color Inconsistency: Uniform coating and excellent ink compatibility ensure consistent color reproduction across all prints.

Peeling Difficulties: The optimized release force allows for easy hot peeling or cold peeling after cooling, depending on your process, without damaging the design.

Why Choose Hanrun paper DTF Film?

Patented Innovation: Years of R&D have resulted in a unique coating formula that outperforms generic films.

Eco-Friendly: All materials meet OEKO-TEX standards, ensuring safe, sustainable printing.

Customer Support: We offer free sample testing, technical guidance, and responsive service to help you achieve optimal results.

Proven Track Record: Trusted by printers worldwide, our film is the choice for high-volume production and premium applications.

Conclusion

Investing in high-quality DTF film is essential for delivering prints that stand out in both appearance and durability. Hanrun paper DTF transfer film, with its advanced technology, strict quality control, and seamless compatibility with EPSON G6070, Roland TY-300, and Mimaki TxF300 DTF printers, is the ultimate solution for businesses seeking excellence in digital textile printing. Say goodbye to printing issues and hello to vibrant, long-lasting designs that exceed customer expectations.

Contact us today to experience the Hanrun paper difference – where innovation meets reliability, and every print is a masterpiece.

Contact Us

Global sales e-mail: info@hanrunpaper.com

Global sales WhatsApp: 86 189 3686 5061

Address: No.10 building, Baijiahui Innovation Community, 699-18 Xuanwu Avenue, Nanjing, China

Need Local Support? Find a Certified Hanrun Paper Dealer in Your Area.

Transfer To Digital, Transfer To Future

Hanrunpaper

Contact us

Address:No.10 building, Baijiahui Creative Community, 699-18 Xuanwu Avenue, Nanjing, China