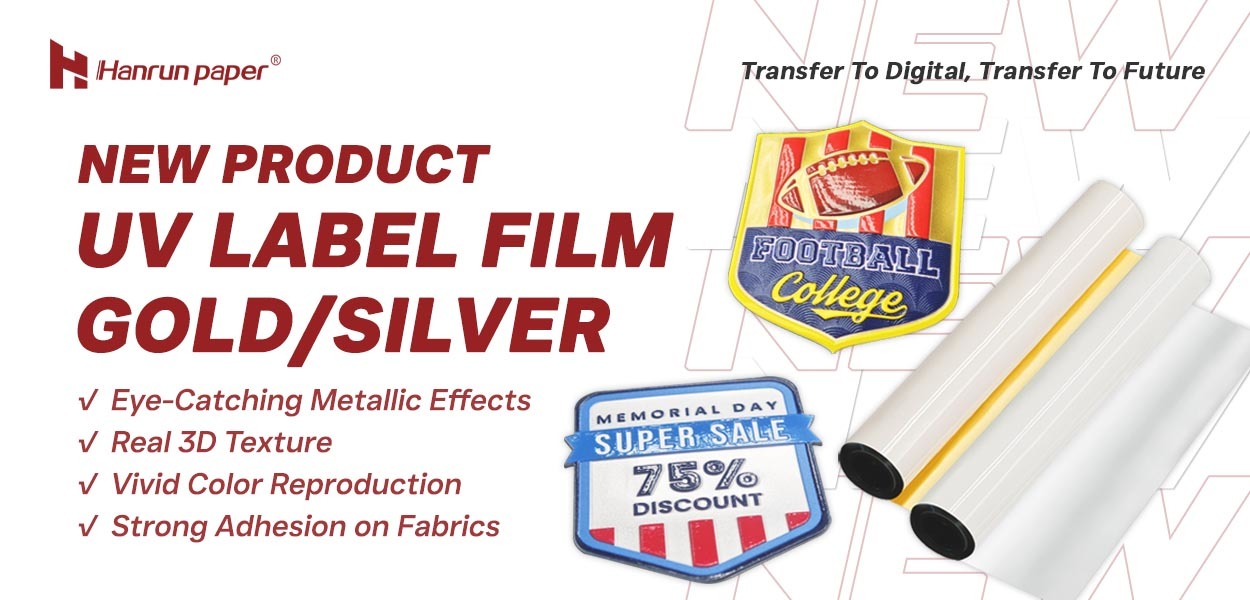

How to Choose High-Quality DTF Film? A Complete Guide from Hanrun Paper

As DTF (Direct to Film) printing technology continues to gain momentum in the textile customization industry, the importance of high-performance DTF film has become increasingly prominent. Whether you are a large-scale garment manufacturer or a startup custom printing studio, the quality of DTF film directly determines the clarity of the printed image, the firmness of the transfer, and the overall stability of the production line.

However, faced with the vast array of DTF films of varying quality on the market, many users find themselves overwhelmed during the selection process. This article will help you understand the film's structural composition, evaluation methods, common issues, and Hanrun Paper's professional strength as a high-quality film supplier.

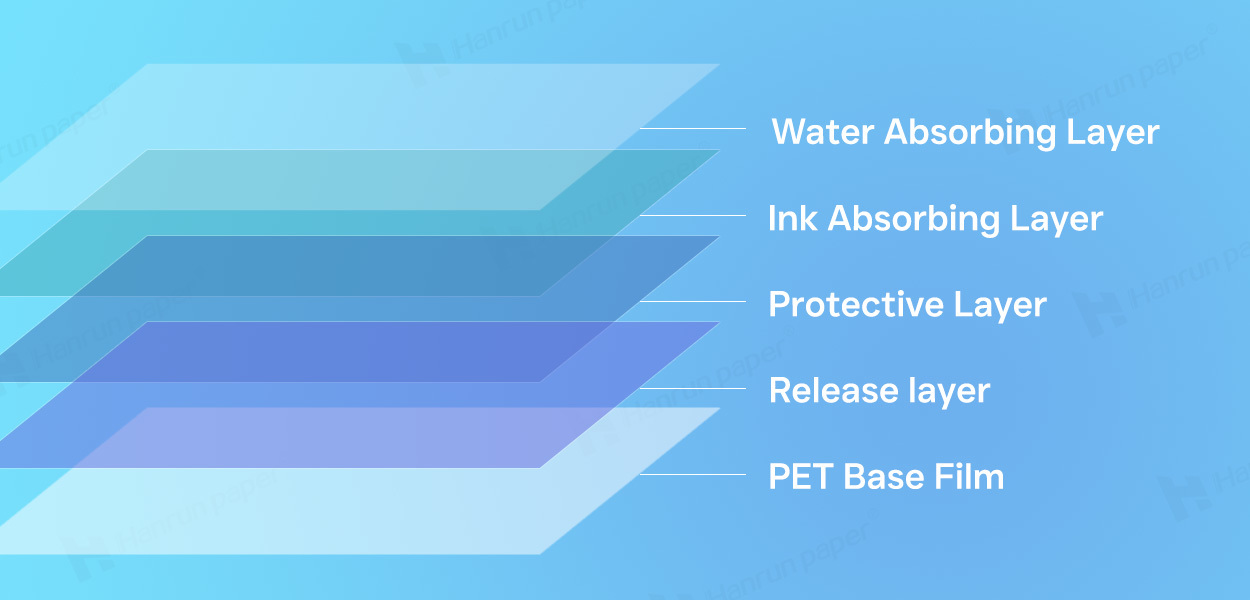

How is DTF Film Made? A Step-by-Step Breakdown

A premium DTF film is not just a simple plastic sheet, but a high-tech material composed of multiple functional coatings. Hanrun Paper DTF film features a five-layer coating structure, with each layer performing a critical function to ensure optimal printing and transfer results:

1. Base Layer (PET Film Substrate)

We use heat-resistant PET (polyester) film with thickness options of 75μm or 100μm. This substrate resists deformation under high temperature and pressure, effectively preventing curling or melting during heat pressing. PET offers excellent physical strength, thermal stability, and compatibility with printing equipment, making it an ideal base for DTF films.

2. Surface Treatment

Before further coating, the base film undergoes specialized surface treatment to regulate the film's release strength. Hanrun Paper controls release force within the range of 280–400g/inch, ensuring the film securely carries the printed image and hot melt powder, while allowing smooth peeling after heat pressing without cracking or residue.

3. Silicone Protective Coating

A thin silicone resin layer is applied to enhance abrasion resistance, anti-static properties, and high-temperature stability. This layer also improves the film's feed performance in the printer, reducing jamming or misfeeds and extending equipment lifespan—an essential feature in industrial-grade, high-speed DTF printing.

4. Release Layer Coating

This layer facilitates the smooth transfer of the printed design from the film to the final substrate. It ensures strong adhesion of the image while maintaining sharpness during the transfer. Hanrun Paper's hot-peel DTF film uses a proprietary blend of release agents and polymers, enabling clean peeling within seconds after heat pressing. It must balance heat resistance and appropriate tack to avoid damage to the image or adhesive residue during peeling.

5. Ink Absorption and Moisture Control Layers

These are the core layers that determine print quality. Hanrun Paper uses a dual-layer composite absorption system:

Ink Absorption Layer: Provides high ink load capacity to ensure rapid ink uptake without bleeding or smudging, producing smooth lines and vivid colors.

Moisture Control Layer: Regulates water dispersion in the ink to prevent edge bleeding or image blurring, especially important for complex graphics or fine text.

All coatings are applied using high-precision automated equipment, with strictly controlled drying temperature and humidity to ensure consistent and stable coating quality across the entire film roll.

Why Is Film Quality So Critical? — Common Problems Caused by Inferior Films

Frequent defects during DTF printing are not always caused by the printer or ink—poor-quality film may be the real culprit. Common issues linked to low-grade DTF films include:

Ink bleeding or color migration: Caused by poor ink absorption or uneven coatings.

Water marks or edge residue: Result from inadequate moisture control, leading to vapor spread beyond image boundaries.

Uneven color or visible noise: Due to inconsistent coating thickness or incompatibility with ink.

Difficult peeling or image tearing: Caused by faulty release layer design that hinders proper hot peel or leaves adhesive residues.

These issues waste materials and time, degrade product quality, and risk customer dissatisfaction.

Hanrun Paper's Rigorous Quality Control – Every Roll is Trusted

DTF film quality control is essential to ensure performance. A comprehensive QC process evaluates all performance metrics, helping select products that meet the highest standards.

1. Appearance Inspection

This first step is crucial, as any defect may impact the final print result.

Coating Uniformity: The film surface must be free of scratches, stains, or residues. Coating should be even, bubble-free, and fully covered.

Thickness Measurement: Coating thickness must meet specifications with a deviation tolerance of ±2.

Edge Inspection: Film edges should be smooth and free from mechanical damage like waves, ensuring easy handling and stable printing.

Release Strength Test: Scraping the film surface with a fingernail must not reveal the PET base.

2. Print Quality Testing

Evaluates clarity, color vibrancy, and detail rendering of printed images.

Ink Compatibility: Tested with EVO and PRO inks across various printers to ensure consistent absorption and accurate color reproduction.

High-Resolution Test: Using 8-pass high-resolution printing under platform heating to verify Pantone and gradient color blocks for uniform color and absence of white spots or ink pooling.

Noise Check: Ensures no visible noise or that any dot noise remains under 0.1mm.

Water Border Test: Verifies that no moisture borders appear around printed areas.

3. Powder Shaking Performance Test

Powder adhesion directly affects transfer quality, especially for premium DTF T-shirt applications.

Heat Deformation Resistance: Film must withstand up to 130°C drying and 160°C heat pressing without yellowing or wrinkling.

Clean Powder Distribution: No hot melt powder should remain on non-printed areas after powder shaking.

White Spot and Snowflake Test: 15-second shake at 130°C must show no white or snowflake marks, ensuring flawless print results.

4. Heat Transfer and Peeling Test

Successful transfer depends on smooth post-press peeling.

Peeling Performance: After pressing at 150°C, the film must allow clean and quick removal of the printed image without damage. Unprinted areas must remain intact.

Oil and Water Return Test: After 2 hours at room temperature, check for any oil or water seepage in printed areas.

Wash Resistance: Subject samples to 1–5 wash cycles to ensure no fading or image peeling, verifying long-term durability in actual use.

How to Store DTF Film Correctly?

Even the highest-quality film may fail if stored improperly. Hanrun Paper recommends:

- Store in a cool, dry environment at 15–24°C with humidity below 60%.

- Use airtight containers such as sealed bags, vacuum packs, or moisture-proof cabinets with desiccants.

- Lay film flat to avoid creasing, stacking pressure, or bending.

- Label each batch clearly with production date, model, and application.

- For bulk users, adopt digital inventory systems and the FIFO (First-In, First-Out) principle.

FAQ

Which side is printable? Usually the matte, slightly textured side. Use backlight, tactile, or water drop tests to identify.

Can DTF film be reused? No. The coating's absorbency is exhausted after first use and cannot support reprinting.

Can sublimation ink be used on DTF film? No. Results are extremely poor—use dedicated pigment ink instead.

What is a double-sided frosted film? The back side is frosted to reduce static and slipping, but only one side is coated for printing.

Why Choose Hanrun Paper?

We are more than a manufacturer—we are a comprehensive DTF solution expert. Since 2020, Hanrun Paper has been a leader in DTF technology. In 2021, we obtained the DTF film invention patent (ZL202110519575.4) and achieved mass production. Today, we hold multiple technology patents for DTF films and printer-integrated technologies. All Hanrun Paper products use eco-friendly materials compliant with OEKO standards. We provide a complete R\&D–production–quality control–after-sales service loop, along with:

- Free sample testing

- Technical adaptation recommendations

- Complete printing + film + powder solution

- Global shipping services

Choose the Right Film to Achieve Perfect Prints

A quality film sets the lower bound for your business performance. Unstable film leads to low efficiency, customer loss, and costly reprints. Hanrun Paper is committed to quality and innovation, delivering reliable DTF film solutions to clients worldwide.

Contact us for free samples and start your premium print journey today!

Contact Us

Global sales e-mail: info@hanrunpaper.com

Global sales WhatsApp: 86 189 3686 5061

Address: No.10 building, Baijiahui Innovation Community, 699-18 Xuanwu Avenue, Nanjing, China

Need Local Support? Find a Certified Hanrun Paper Dealer in Your Area.

Transfer To Digital, Transfer To Future

Hanrunpaper

Contact us

Address:No.10 building, Baijiahui Creative Community, 699-18 Xuanwu Avenue, Nanjing, China