What Is Real Professional Print Color Management?

As global brand owners, retailers, and premium buyers continue to raise their expectations for print quality, color accuracy and consistency have become a fundamental requirement rather than a value-added feature.

From textile digital printing and sublimation printing to UV printing and DTF printing, professional print color management is now a core competency that modern printing companies can no longer ignore.

However, despite its frequent use, color management is also one of the most misunderstood concepts in the printing industry.

Some believe calibrating a printer is enough.

Others assume that having ICC profiles automatically guarantees accurate color.

Many even confuse ink preset curves with true color control.

So what does real color management actually mean?

This article provides a systematic examination of the complete print production workflow, combining traditional printing and digital printing practices, to explain what professional color management truly entails and how it delivers predictable, repeatable, and standardized color results.

What Is Color Management? One Core Objective

At its core, color management is the systematic control of color reproduction throughout the entire production process.

The ultimate goal is simple:

To achieve consistent, predictable, and repeatable color across different devices, materials, processes, and production batches.

This goal can be broken down into two key dimensions:

1. How color is managed

Modern color management relies on:

- Scientific color management methodologies

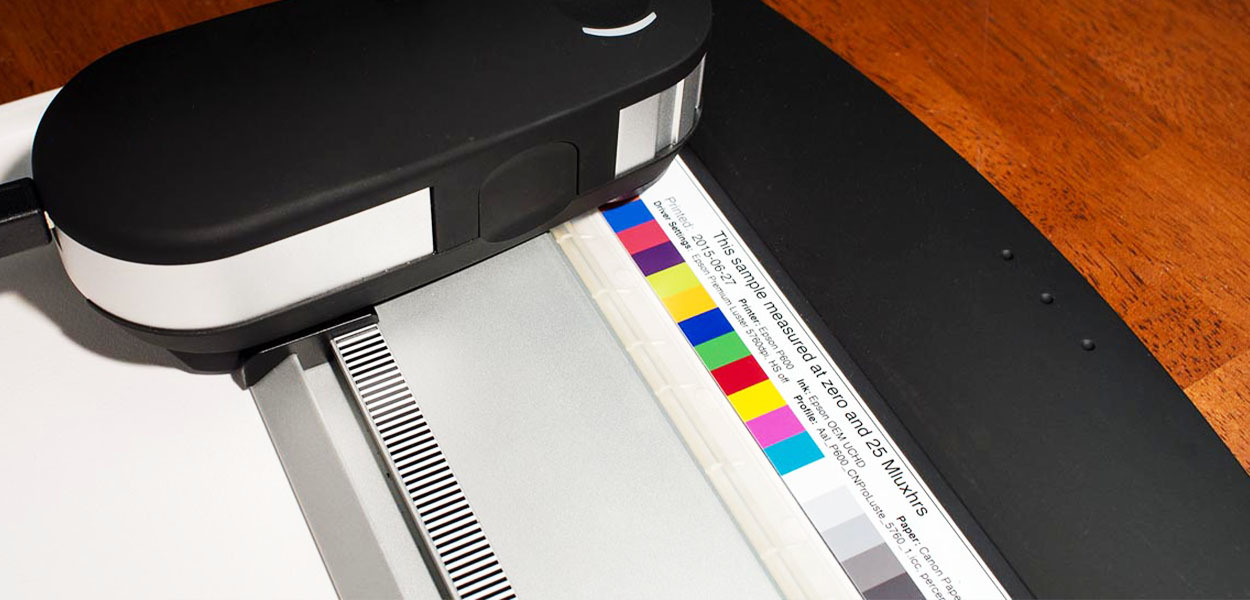

- Data-driven measurement instruments (spectrophotometers, densitometers)

- Software systems such as RIPs, DFEs, and ICC-based workflows

- Standardized equipment maintenance and material control

- Well-defined operational procedures and management policies

2. What results are achieved

Effective color management typically delivers:

- Visual matching between print output, digital proof, and customer reference

- Measured color differences (ΔE) within acceptable tolerances

- Stable color performance across production batches

- Reduced reprints, revisions, and setup waste

- Compliance with ISO color standards and industry certifications

Front-End Image Editing: The Most Overlooked Color Control Step

In high-end printing environments, front-end color correction and image editing are often the most underestimated yet impactful part of color management.

Professional color specialists typically:

- Have years of experience judging and correcting color

- Understand printing characteristics and material behavior

- Master ICC color spaces and color conversion logic

Their responsibilities often include:

- Adjusting image files based on customer color references or historical samples

- Editing CMYK data under defined ICC conditions

- Re-separating heavy ink files using long-black or optimized separation strategies

- Converting files from customer color spaces to actual production color spaces

The advantage of front-end color correction is efficiency:

problems are solved before they reach the press, rather than forcing machines to compensate for flawed files.

For DTF printing, textile digital printing, and sublimation printing, where color sensitivity is extremely high, front-end color work often determines the success of the final output.

Soft Proofing: The First Digital Color Checkpoint

Soft proofing, or screen proofing, is an essential component of modern digital color management.

Its principle is straightforward:

A properly calibrated monitor is used to simulate the final print color.

Since displays operate in RGB color space—which is theoretically larger than CMYK—they can accurately preview print colors when managed correctly.

Key requirements for reliable soft proofing:

- A professional-grade graphics monitor

- Hardware calibration using dedicated software and spectrophotometers

- Accurately monitor ICC profiles

- Correct settings for brightness, white point, and gamma

Equally important are:

- Post-calibration color validation

- Enabling “simulate paper white” during preview

- Viewing under standardized D50 lighting conditions

Soft proofing is especially valuable for remote proofing, international collaboration, and digital printing workflows, even though environmental and hardware variables must be carefully controlled.

Contract Proofing: The Signature of Professional Color Management

If soft proofing is about visualization, contract proofing is about physical verification.

A truly professional digital proofing system is not just a printer—it is an ecosystem that includes:

- High-gamut inkjet proofing devices

- Professional proofing software with ISO standards built in

- Precision measurement instruments

- Certified proofing inks and media

- Ongoing technical support and calibration services

The objective is clear:

The proof must accurately predict the final print result.

By regularly measuring Fogra or IDEAlliance control strips and evaluating them according to ISO 12647-7, printers can establish a closed-loop color management system.

This is particularly critical in UV printing, textile printing, sublimation printing, and DTF workflows, where material variability is high.

Digital Printing: A New Color Management Battleground

With the rapid growth of digital textile printing, sublimation printing, UV printing, and DTF printing, digital presses have become a major focus of color management.

Digital printing color management typically serves two main purposes:

1. High-accuracy proofing and reprints

- The device color gamut must be sufficient to match the target print standards

- ICC profiles are used for device-to-device matching

- Performance is evaluated using ISO metrics such as average and maximum ΔE

2. High-end commercial output

Even for jobs that do not require strict print matching, proper gray balance, tone reproduction, and gamut utilization can significantly elevate visual quality.

Large-format inkjet printers and UV printers, when properly managed, often outperform traditional CMYK printing in color vibrancy and saturation.

Conventional Printing: The Foundation of Color Management

For offset and UV offset printing, color management remains the primary production discipline.

Achieving stable color requires control over:

- Press stability and maintenance

- Standardized consumables (ink, paper, plates, blankets)

- Dot gain compensation, TVI, and G7 gray balance

- Process monitoring and data documentation

Once stabilized, presses can generate reliable printing ICC profiles, enabling accurate matching between contract proofs, digital printing, and traditional printing.

Press Linking, Spot Color Control, and Process Extensions

It is important to clarify a common misconception:

Ink preset curves are not color management.

Press linking improves efficiency, but true color management also includes:

- Spot color formulation and database management

- SCTV-based spot color tone control

- CxF spot color data exchange

- Compensation for varnishing, lamination, and coating effects

These aspects are especially critical in packaging printing, label printing, and UV printing applications.

Wide Color Gamut Printing: Advanced Color Management

Once a stable color management foundation is established, many brands pursue wide color gamut printing.

Whether achieved through:

- High-density CMYK printing

- Or fixed seven-color (CMYK+OGV) systems

The prerequisites remain the same:

stable equipment, controlled consumables, standardized workflows, and measurable data.

Only under these conditions can wide color gamut printing deliver consistent, competitive advantages.

No Universal Formula—Only the Right Strategy

There is no one-size-fits-all solution for color management.

Each printing company must evaluate:

- Its customer requirements

- Application focus (textile, sublimation, UV, DTF, packaging)

- Equipment configuration

- Budget and internal expertise

True professional color management is not about copying templates—it is about building a system that solves real problems, supports growth, and ensures long-term color consistency.

Contact Us

Global sales e-mail: info@hanrunpaper.com

Global sales WhatsApp: 86 189 3686 5061

Address: No.10 building, Baijiahui Innovation Community, 699-18 Xuanwu Avenue, Nanjing, China

Need Local Support? Find a Certified Hanrun Paper Dealer in Your Area.

Transfer To Digital, Transfer To Future

Hanrunpaper

Contact us

Address:No.10 building, Baijiahui Creative Community, 699-18 Xuanwu Avenue, Nanjing, China

Quick Links