Why Do Inkjet Printheads Fail? How Can You Prevent It?

In the world of printing—whether it's for home use, business offices, or industrial production—the inkjet printhead is the heart of the printer. Whether you're operating a DTF printer, UV printer, or a wide-format digital inkjet machine, the final print quality and system longevity largely depend on the condition of the printhead.

But why do printheads fail? What are the differences between various printhead types? And how can you extend their lifespan? This comprehensive guide examines the primary causes of inkjet printhead failure and provides practical advice for printhead maintenance, enabling you to make informed decisions while saving time, money, and hassle.

Why the Inkjet Printhead Matters: More Than Just a Component

Think of a printer as an orchestra, and the printhead as the lead performer. Without it, the entire system falls out of harmony. The printhead's job is highly precise: it controls the ejection of ink droplets onto the substrate (such as paper, fabric, or film), ensuring every dot of ink lands exactly where it should. Even a minor issue, such as nozzle clogging or droplet misalignment, can ruin an entire batch of prints.

For businesses, a failed printhead isn't just an inconvenience. It can result in missed deadlines, wasted materials, and lost client trust. For home users, it leads to reprints and unnecessary replacement costs. Therefore, understanding how the printhead works, its risks, and how to properly maintain it is key to efficient, low-cost printing.

Common Causes of Inkjet Printhead Failure

Most printhead failures stem from improper maintenance, incorrect usage, or unfavorable environmental conditions. Below are the most common culprits—and how to avoid them:

1. Dust and Environmental Contaminants

Microscopic dust particles (often >1 micron) are silent killers. Once they enter the ink system or cartridge, they can permanently block nozzles, which are difficult to clean with standard solutions.

Prevention:

Operate in a clean, dust-free workspace. Maintain ideal temperature and humidity levels, regularly wipe down the printer's exterior, and consider using air filtration systems when necessary.

2. Using Poor-Quality or Incompatible Ink

Not all inks are created equal. Generic or third-party inks not certified by your printer manufacturer can cause chemical reactions: ink may dry inside the nozzle, form clogs, or contain heavy metals and salts that corrode the nozzles over time.

Prevention:

Always use OEM-recommended ink or high-quality compatible ink formulated for your specific printhead. These options reduce wear and chemical damage.

3. Cleaning with Improper Solvents

Some users mistakenly use tap water, isopropyl alcohol, or ammonia to clean printheads. These harsh solvents can permanently damage nozzle components and internal electronics.

Prevention:

Use manufacturer-approved cleaning solutions designed for your printhead type. They clean effectively without causing damage.

4. Mechanical Damage from Media

Curled, wrinkled, or damp substrates may contact the printhead and damage its delicate resistors or electronics.

Prevention:

Always ensure substrates are flat, dry, and properly aligned before printing. Handle media with care to avoid head strikes.

5. Prolonged Inactivity

Printheads need regular use. Leaving a printer idle for weeks can cause ink to dry inside the nozzles, leading to clogs and performance issues.

Prevention:

Print a test page weekly and run the printer's automatic cleaning cycle. If storing the printer for a long time, follow the manufacturer's guide to empty or seal the ink system.

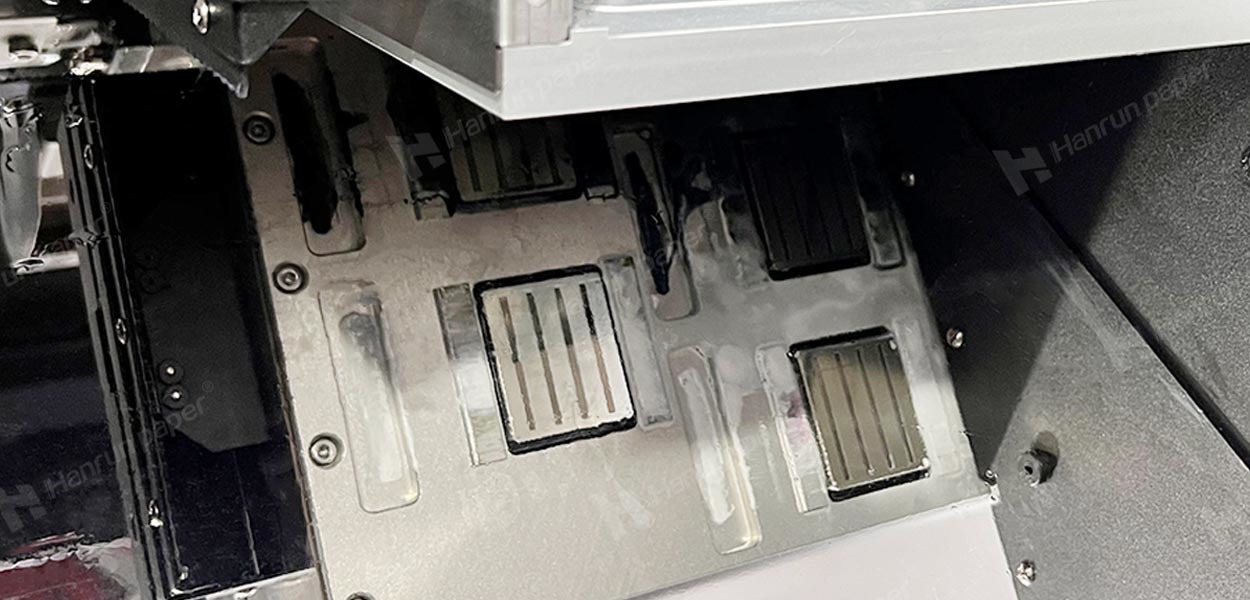

6. Poor Ink System Maintenance

The ink system includes filters, dampers, wiper blades, and capping stations. If these components are dirty or worn, debris can reach the printhead.

Prevention:

Replace filters and dampers regularly. Clean the wiper blade and capping station according to your printer's manual.

7. Extreme Environmental Conditions

Inks and printers operate best within a specific “comfort zone.” Recommended ink storage temperatures are 10–35°C; optimal printer operation is at 15–25°C. Humidity and heat sources like dryers can negatively affect performance.

Prevention:

Use a thermo-hygrometer to monitor conditions. Avoid placing printers near open windows or heaters.

Understanding Printhead Types: Choose What Fits Your Needs

Different types of inkjet printheads operate based on distinct technologies. Understanding these differences can help you choose the right equipment based on speed, precision, and ink compatibility.

Piezoelectric Printheads

Piezo printheads use crystals that bend when electrically charged, pushing ink out of the nozzle.

Advantages:

- Versatility: Compatible with water-based, solvent, and UV-curable inks (no heat required).

- Durability: Longer lifespan compared to thermal printheads.

- Precision: Can eject variable droplet sizes (ideal for grayscale printing).

Leading brands: Epson, Fujifilm Dimatix, Konica Minolta.

Thermal Inkjet Printheads

These use heat to create a vapor bubble that propels ink droplets.

Advantages:

- Cost-effective: Lower manufacturing cost; widely used in home and office printers.

- Ease of use: Often integrated with cartridges for quick replacement.

Limitations:

- Shorter lifespan.

- Fixed droplet size (not grayscale capable).

Main manufacturers: HP, Canon.

Grayscale vs Binary Printheads

- Grayscale printheads eject variable-sized ink droplets (from a few picoliters to over 50), enabling smooth gradients and sharp detail—ideal for photo and high-resolution graphics.

- Binary printheads produce uniform droplets ("on/off" state), making them faster and more suitable for high-volume tasks like coating primers or varnish.

Single-Pass vs Multi-Pass Printheads

- Single-pass: The printhead is fixed while the media moves beneath it. Designed for high-speed, industrial printing (e.g., textiles, corrugated packaging).

- Multi-pass: The printhead moves back and forth over the media, building the image in layers. Best for small-batch or high-precision work.

Frequently Asked Questions

Q: What is the typical lifespan of an inkjet printhead?

A: It depends on usage and maintenance. Piezo printheads can last 1–3 years with proper care. Thermal printheads may need replacement every 6–12 months.

Q: Can a clogged printhead be fixed?

A: Sometimes. Try using the OEM cleaning solution first. If the clog is severe (caused by dried ink or debris), it may require professional service or replacement.

Q: Are laser printers better than inkjet printers in terms of printhead issues?

A: Laser printers don't use printheads; they rely on toner and laser imaging. Inkjet printers offer superior color accuracy and media versatility, while laser printers are optimized for high-volume monochrome jobs.

Q: What's the most common mistake users make with printheads?

A: Using non-original ink. It's the leading cause of clogging, corrosion, and premature printhead failure.

Conclusion

Understanding the causes of inkjet printhead failure is the first step to reducing downtime and improving print quality. By:

- Using OEM or high-quality compatible ink

- Maintaining a stable print environment

- Following regular cleaning and maintenance schedules

You can extend the life of your printhead, boost printing stability, and keep your business running smoothly.

Contact Us

Global sales e-mail: info@hanrunpaper.com

Global sales WhatsApp: 86 189 3686 5061

Address: No.10 building, Baijiahui Innovation Community, 699-18 Xuanwu Avenue, Nanjing, China

Need Local Support? Find a Certified Hanrun Paper Dealer in Your Area.

Transfer To Digital, Transfer To Future

Hanrunpaper

Contact us

Address:No.10 building, Baijiahui Creative Community, 699-18 Xuanwu Avenue, Nanjing, China