Choosing Sublimation Paper: Which GSM Is Right for You?

In the fast-growing world of digital textile printing, sublimation paper plays a critical role in determining the final print quality. While many users focus on printer models and ink types, the importance of sublimation paper weight is often underestimated. The weight of sublimation paper, measured in grams per square meter (gsm), affects not only print quality but also ink absorption, drying time, transfer rate, and cost-efficiency.

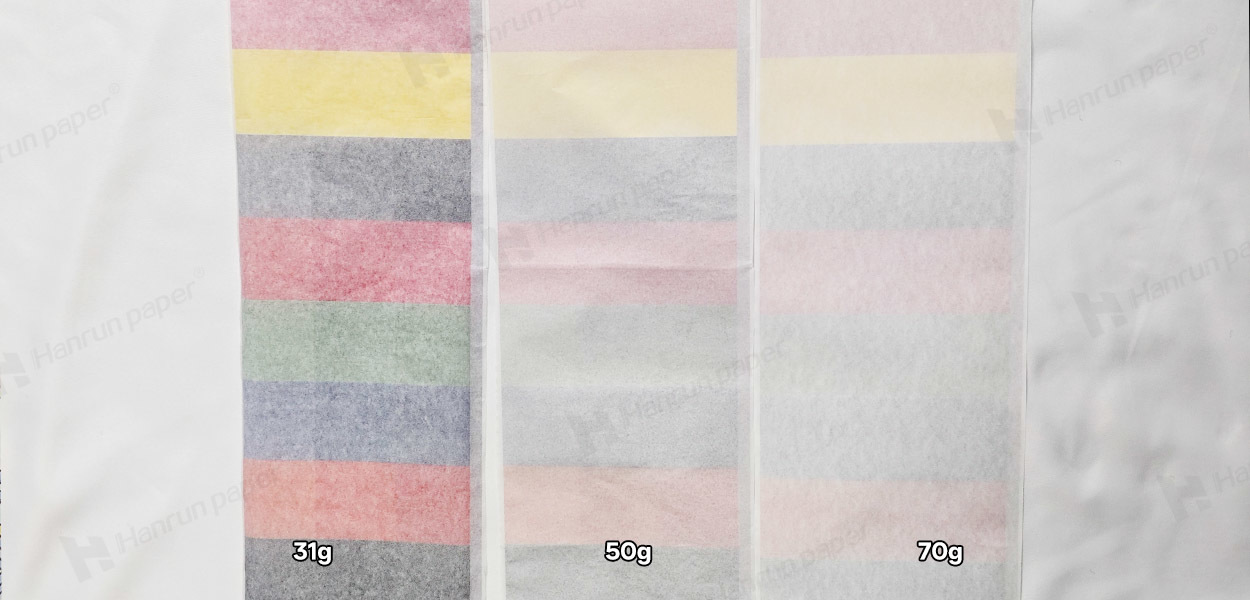

This guide provides an in-depth comparison of commonly used sublimation papers: 31g, 50g, and 70g. Based on controlled testing and real-world applications, we'll help you understand which paper weight best suits your production needs.

Understanding Sublimation Paper Weight

Sublimation paper weight refers to how much a square meter of paper weighs. Lighter paper (e.g., 31g) uses less pulp and is generally more cost-effective and flexible. Heavier paper (e.g., 70g) is denser, more stable during printing, and better suited for high-ink or complex designs.

Choosing the right weight of sublimation paper can:

- Improve print flatness and consistency

- Reduce ink bleeding and ghosting

- Increase transfer efficiency

- Enhance color brightness and sharpness

- Reduce production costs when properly matched to the application

Test Overview: 31g vs 50g vs 70g Sublimation Paper

To assess performance differences, we conducted a standardized test using the same graphic (high ink volume, full color), printer, and fabric. The only variable was paper weight. Here's what we found:

31g Sublimation Paper – Lightweight and Economical

Pros:

- Lower cost per sheet

- Faster drying due to the thin coating

Cons:

- Prone to wrinkling during printing, especially with heavy ink loads

- Severe ink bleed-through

- Low transfer rate, with significant ink residue left on paper

- The final image lacks vibrancy and detail sharpness

Best suited for:

- Simple graphics with low ink density

- Light-colored designs

- Cost-sensitive applications like temporary signage, giveaways, mock-up production

50g Sublimation Paper – Mid-Range Versatility

Pros:

- Improved stability compared to 31g

- Moderate ink absorption

- More consistent transfer quality

Cons:

- May show some “fish-scale” buckling on wide-format or high-ink images

- Slight backprint may still occur

Best suited for:

- Standard garment printing (e.g., T-shirts, tote bags)

- Low-to-medium ink saturation designs

- Businesses balancing cost and performance

70g Sublimation Paper – Heavyweight for High-Quality Output

Pros:

- Excellent stability during printing

- Minimal wrinkling or warping

- Highest ink retention and transfer rate

- Produces vivid, saturated colors with crisp detail

- Lowest level of backprint

Cons:

- Slightly higher material cost

Best suited for:

- High-end textile printing (sportswear, curtains, upholstery)

- Complex, full-color or high-resolution designs

Ink Control and Image Matching: Optimize for Best Results

In addition to testing the same graphic on all paper types, we also printed tailored graphics with ink volumes optimized for each paper weight. The results showed that adjusting designs to match paper capacity significantly improved print flatness and transfer efficiency on lighter papers.

For example:

- Reducing ink density on 31g paper minimized wrinkling and ghosting

- Balanced ink levels on 50g paper improved image sharpness

- Even 70g paper benefited from slight ink adjustments for faster drying

This proves that paper performance is not only about GSM—it's also about how well you manage ink load and graphic composition.

How to Choose the Right Sublimation Paper Weight

When selecting sublimation paper, consider the following factors:

1. Print Complexity and Ink Volume

For bold, vibrant graphics with rich colors, 70g or higher is preferred

For low-ink or light designs, 31g or 50g may suffice

2. Fabric Type

Denser fabrics benefit from higher GSM paper due to better ink retention

Thin or temporary-use fabrics may work well with lower GSM paper

3. Cost Management

Consider the trade-off between print quality and material cost

Properly optimizing your design and ink volume can make lower GSM paper a viable option for many applications

Tailor Your Paper Choice to Your Business Goals

There's no one-size-fits-all sublimation paper. The ideal GSM depends on your printing needs, product type, and budget. At Hanrun Paper, we offer a full range of sublimation papers from 29g to 120g, designed to meet the varied needs of printers across the globe. Whether you're printing fashion garments, home textiles, or promotional items, we have the right sublimation paper for you.

Contact us today to request free samples, get expert advice, and elevate your sublimation printing with the perfect paper solution.

Contact Us

Global sales e-mail: info@hanrunpaper.com

Global sales WhatsApp: 86 189 3686 5061

Address: No.10 building, Baijiahui Innovation Community, 699-18 Xuanwu Avenue, Nanjing, China

Need Local Support? Find a Certified Hanrun Paper Dealer in Your Area.

Transfer To Digital, Transfer To Future

Hanrunpaper

Contact us

Address:No.10 building, Baijiahui Creative Community, 699-18 Xuanwu Avenue, Nanjing, China