Complete DTF Workflow Solution: Faster, Easier, and More Profitable

In the garment printing industry, success hinges on efficiency, consistency, and effective cost control. That's why Hanrun Paper offers a comprehensive DTF workflow solution—from consumables to equipment—designed to maximize productivity with minimal labor.

Why a Complete Workflow Matters

When evaluating production investment, four key factors stand out:

- High Efficiency – With an integrated DTF printing setup, output can reach up to 500 T-shirts per hour, enabling you to meet bulk orders with ease.

- Cost-Effective – Each garment costs only around $2.67 to produce, ensuring high profitability and scalability.

- Quality – A seamless workflow guarantees stable and consistent results, so every print maintains vibrant color and fine detail.

- After-sales support – Beyond hardware, our service team provides timely on-site assistance, helping you minimize downtime and maximize productivity.

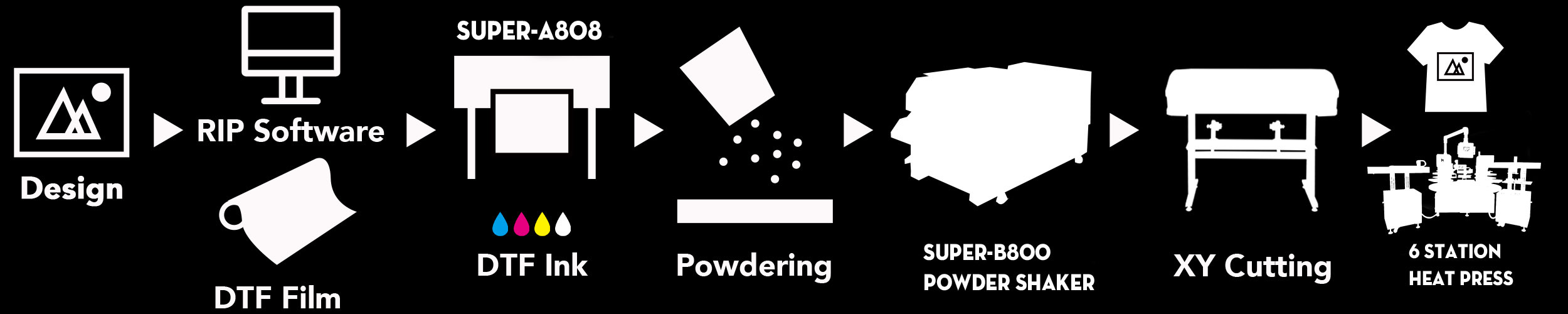

The Workflow Step by Step

1. Printing – Super A-808 DTF Printer

The workflow begins with Hanrun paper DTF film and OEKO-TEX certified DTF ink, delivering vivid colors and fine detail. Powered by 8 industrial-grade printheads and 13-color printing capability, the Super A-808 achieves exceptional color accuracy and 30% lower production costs. With its 800mm printing width and smart automation, it supports high-volume continuous printing—making it the industry's true game changer.

2. Powder Shaking – Super-B800 DTF Powder Shaker

Next, the Super-B800 Powder Shaker ensures automatic, even powder application and precise curing. Featuring 800mm wider drying capacity, intelligent powder recycling, and advanced oil smoke removal, it keeps the workspace clean while reducing waste and power consumption. The result: better film adhesion, smoother surfaces, and a healthier production environment.

3. Cutting – C-800 XY Automatic Cutter

After curing, the C-800 XY Cutter takes over. With dual-round blades and a visual positioning system, it delivers precise horizontal and vertical cutting. Fully automated, it reduces manual work, improves accuracy, and saves significant time. This ensures fast, clean, and efficient transfer preparation—perfect for both small studios and industrial setups.

4. Heat Transfer – Super-F4050-6 Automatic Heat Press

Finally, the Super-F4050-6 Automatic Heat Press completes the workflow. Featuring a 6-station rotary system, automatic film pickup, film peeling, and garment collection, it allows continuous, high-volume production with only one operator. Precise temperature and pressure control guarantee uniform results while minimizing waste.

5. The Finished Garment

The result is a vibrant, durable, and professionally finished product—ready for retail, fashion, or personalized customization.

One-Stop Solution for Every Business

From DTF film and ink to printing, powdering, cutting, and heat pressing, Hanrun Paper provides a true one-stop solution. Whether you're starting a new printing business or scaling up for industrial production, our workflow empowers you with:

- Higher efficiency

- Lower labor cost

- Stable output

- Safer, cleaner operation

With the right workflow, your DTF business becomes faster, easier, and more stable, ensuring that you stay ahead of the competition.

Ready to upgrade your production?

Contact us today to start your complete DTF production journey.

Contact Us

Global sales e-mail: info@hanrunpaper.com

Global sales WhatsApp: 86 189 3686 5061

Address: No.10 building, Baijiahui Innovation Community, 699-18 Xuanwu Avenue, Nanjing, China

Need Local Support? Find a Certified Hanrun Paper Dealer in Your Area.

Transfer To Digital, Transfer To Future

Hanrunpaper

Contact us

Address:No.10 building, Baijiahui Creative Community, 699-18 Xuanwu Avenue, Nanjing, China