How to Create UV 3D Labels – A Digital Printing Solution for Apparel Customization

In the textile industry, including garments, hats, and bags, product labels are not only key to brand identification but also vital in enhancing the perceived value and personalization of items. Traditional label methods, such as screen printing or embroidery, provide a tactile finish but often fall short in meeting the growing demand for flexible, small-batch customization due to their high setup costs, long lead times, and complex processes.

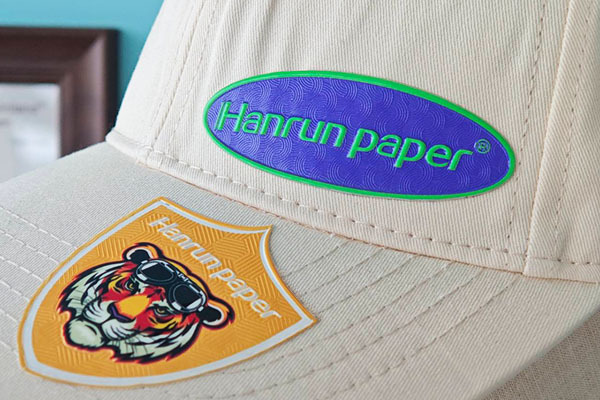

Today, we introduce an innovative label-making solution—UV 3D Labels (Heat-Press UV 3D Labels). This method combines UV printing with heat press transfer, using Hanrun Paper's UV label film and UV soft ink to produce high-resolution, cost-effective, and durable labels with excellent adhesion. It is especially suitable for use on soft materials such as clothing, shoes, hats, and canvas bags.

What is a UV 3D Label?

UV 3D Labels are created by printing embossed textures onto self-adhesive TPU-based UV label film using UV printing technology, followed by heat press transfer to fabric surfaces. The result is a durable, visually striking label with a pronounced 3D texture, while maintaining flexibility and resistance to deformation.

Key Differences Between UV 3D Labels and UV DTF Labels (Crystal Stickers):

| Aspect | UV 3D Labels | UV DTF Labels (Stickers) |

| Ink Type | UV Soft Ink | UV DTF Ink |

| Printing Media | UV Label Film (TPU-based) | UV DTF Film (PET-based) |

| Application Method | Heat Press Transfer | Direct Adhesion |

| Application Surface | Soft materials (fabric, apparel) | Hard surfaces (glass, plastic, metal) |

| Features | Flexible, heat-pressable, washable, deformation-resistant | Rigid, waterproof, sunproof, embossed |

Core Advantages of UV 3D Labels

Compared with traditional screen-printed, embroidered, or vinyl cut labels, UV 3D Labels offer several distinct advantages:

1. Digitally Driven, On-Demand Production

No mold-making required, zero minimum order quantity

Design changes can be implemented instantly, reducing upfront cost

2. Distinct 3D Textures

White ink stacking combined with varnish coating creates embossed effects

Supports gradient colors and intricate designs for enhanced visual impact

3. Instant Curing and High Production Efficiency

Uses LED UV curing technology for rapid drying without additional drying time

Eliminates the need for extra powdering or drying equipment, saving space

4. Flexible and Durable for Heat Transfer

UV soft ink resists collapsing or cracking during heat press

Wash-resistant, high-temperature tolerant—ideal for high-use apparel

Exclusive Benefits of Hanrun Paper UV Label Film & UV Soft Ink

Features of UV Label Film

TPU base with adhesive backing, ideal for heat pressing onto various textiles

Excellent ink absorption and image clarity

Maintains shape under high-temperature pressing, with strong adhesion and no edge curling

Features of UV Soft Ink

Low-odor, eco-friendly formula suitable for studios and commercial use

Supports multi-layer white ink stacking for pronounced texture

Maintains softness after heat pressing, resists bending, washing, and UV exposure

Compatible with most UV flatbed printers, including Epson, Mimaki, and Roland systems

Full Workflow: How to Make UV 3D Labels (Step-by-Step for Beginners)

Even if you're new to digital printing, this guide will help you easily create high-quality UV 3D labels.

Step 1: Design and Layer Preparation

Use software such as Adobe Illustrator, Photoshop, or CorelDRAW to design your label graphics. Vector files or high-resolution images are recommended. Ensure the design is layered as follows:

White Ink Layer: For the base and texture stacking.

Color Layer: For the visible graphic design.

Varnish Layer: To enhance gloss and surface protection.

Export the file in PNG or TIF format with a resolution of at least 300 dpi.

Step 2: Print Settings and Operation

1. Material Placement: Place Hanrun Paper UV label film on the UV flatbed printer, with the printable side facing up.

2. Print Sequence Configuration:

White Ink Stacking: Configure the printer to output white ink only at double ink volume. Repeat the process to build up 6–8 layers of texture.

Color and Varnish Printing: Switch to print mode for white + color + varnish. The varnish layer adds gloss and surface protection. Each layer is instantly cured using LED UV light during printing to ensure rapid solidification.

Step 3: Contour Cutting

Use a laser cutter to follow the design path and cut the label to shape.

Ensure clean, smooth edges with no scorching or distortion.

Peel off excess material, leaving the finished label intact and ready for transfer.

Step 4: Heat Press Transfer

1. Peel off the backing film and position the label design onto the desired area of the fabric.

2. Set the heat press machine with the following parameters:

Temperature: 160°C / Time: 15 seconds / Pressure: Medium (sample testing is recommended)

3. After pressing, allow the label to cool. Once cooled, the label will be firmly bonded to the fabric, completing the application process.

Step 5: Optional Durability Testing

Bend Test: Repeatedly bend the label to ensure it doesn't crack or peel

Wash Test: Conduct 5–10 standard wash cycles to evaluate colorfastness

UV/Weather Resistance Test: Expose to sunlight and humidity to verify long-term durability

Conclusion

UV 3D label technology presents a cutting-edge solution for the apparel and accessories industry. It combines the speed and flexibility of digital printing, heat transfer's durability, and UV ink's stunning texture effects. This approach not only meets the demand for high-quality, personalized labeling but also significantly reduces the production threshold and cost.

By choosing Hanrun Paper's UV Label Film and UV Soft Ink, you gain access to a stable, efficient, and eco-friendly digital labeling solution. Contact us today for free samples and technical support—we'll help you get started and unlock more UV printing possibilities.

Contact Us

Global sales e-mail: info@hanrunpaper.com

Global sales WhatsApp: 86 189 3686 5061

Address: No.10 building, Baijiahui Innovation Community, 699-18 Xuanwu Avenue, Nanjing, China

Need Local Support? Find a Certified Hanrun Paper Dealer in Your Area.

Transfer To Digital, Transfer To Future

Hanrunpaper

Contact us

Address:No.10 building, Baijiahui Creative Community, 699-18 Xuanwu Avenue, Nanjing, China